| Complete X-Ray Systems

|  |

UNIVERSAL AUTOMATED

X-RAY TELEVISION COMPLEXES “FILIN”

for industrial radiography and radioscopy

In the modern industry the problem of the reliability of product released becomes more and more sharp. At present X-raying is one of the most reliable and informative methods for the quality control. X-ray control method is equally good both for the investigations and adjustment of technologies and for 100% control of bulk products.

For the suitable use and increase of control efficiency several versions of universal automated X-ray television complexes are developed and produced. They are designed for the application in different branches of industry, such like metallurgical, car, aircraft, nuclear, chemical and others. By request of the client we finalize the design of basic complexes for the solution of specific tasks, thus producing many special systems.

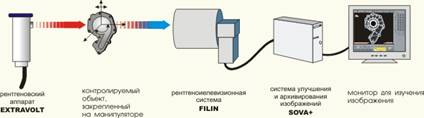

Classic pattern of X-ray television examination is shown on the figure.

The X-ray radiator is located from the one side of the object under examination. The radiator could be completed with X-ray radiation shutter and limiting diaphragm of the beam. The image receiver (X-ray electronic optics, flat panel detector, FOSFOMATIC plate) is located from the other side. The receiver can be completed with shutters for the protection against direct radiation. The object under investigation is fixed to the manipulator. In the majority of cases the 5-axe manipulator is used that provides the movement of the object within 3 planes, its inclination and turn. X-ray radiation passing through the object forms the shadowgraph on the screen which is transferred to the system of the image improvement and displayed on the monitor.

If the object under examination has big overall dimensions, it could be stationary positioned, and the radiator and image receiver are fixed on the manipulator, ensuring the examination of the object in necessary projections. More often these methods have to be combined. In this case part of freedom degrees are in possession of the object under examination, and another part - in the possession of the radiator with receiver. The examination of the object under all possible angles is achieved by moving the controllable object and components of X-ray TV-set.

Universal complexes allow the radiographic inspection of rather large industrial products mix, however in most part of cases to achieve the high capacity the finalization of universal constructions is required in order to fulfill the specific task of the examination of certain types of the products.

The most difficult task consists in making this system functional. It should fulfill the task put without making anything extra. The creation of such complexes represents the main part of our work for industrial radiography and radioscopy. Only in this case the system would be reliable and convenient for the use. Over more than 10 years of our work we succeeded in embodying many wishes of our clients and create dozen types of X-ray systems. Practically it is impossible within the bounds of this site to describe all modifications available. Below you find some more or less standard X-ray complexes. As a matter of customer convenience we split the complexes into 4 series, differing from each other by their functional capabilities.

For more detailed information and for requests to develop the system in accordance with your requirements, please, apply to specialists of our company by phone +7 (812) 380-6202 or use the feedback link on the site. Engineers of the company TESTRON would help you in solving your tasks, using the comprehensive approach to the equipment design.

|

Universal radiographic/radioscopic complexes of series FILIN-102 |

Cheap compact complexes, designed for the examination of the pieces, put on the object stage, in one projection. The X-ray unit together with vertical mechanism, moving the X-ray tube, is located inside the compact cabin which is protected against X-rays impact. Inside this cabin there is also a table for radiographic inspection.

This system could be also used for the examination of any objects from different materials. The size of the object should not exceed the dimensions of the object stage. The systems are very compact. To save the space the X-ray generator is located just under the system. For the convenience of putting the objects the height of sliding table is set to approximately 700mm.

Maximum voltage: up to 450 kV

Dimensions of the object stage: up to 1200 x 600 mm

Total weight of the objects: up to 150 kg

Depth of radiographic inspection in terms of steel: up to 120 mm

Working cycle: 24 hours a day

add to cart add to cart

delete from cart delete from cart

|

|

|

Universal X-ray television complexes of series FILIN-122 |

They are designed for the examination, in real time as well, of large products mix of up to 100kg weigh in different branches of industry. They could be easily adapted to solve the tasks of fully automated control and rejection of details. The complexes are put inside their own X-ray protected cabins and could be located practically in any place of production area.

The systems of series FILIN-2xx, equipped wit certain types of detectors, could operate in the mode of 3-D-tomography.

add to cart add to cart

delete from cart delete from cart

|

|

|

FILIN X-ARM [C] - универсальные рентгенотелевизионные комплексы с манипулятором типа "C-ARM" |

To examine carters of gearboxes, engine basic blocks, pump bodies and other light-alloy and heavy castings.

The complex consists of:

- high-stabilized X-ray unit EXTRAVOLT-160 with programmable control and closed water cooling system.

- X-ray television system FILIN-9H765M together with the system for digital processing and archiving of images, SOVA+ +

- programmable manipulator of the object with five degrees of movement freedom

- automated shutter of the beam

- automated shutters of X-ray electro-optics

- cabinet with programmable controller of power supply to gearboxes of the motors and with switch panels

- cabin of radiation protection on 160kV with TV system to observe the object position

» Details

add to cart add to cart

delete from cart delete from cart

|

|

|

UNIVERSAL COMPLEX “FILIN -239/225” |

To inspect components of fuel systems, pumps, light-alloy and heavy castings.

The complex consists of:

- high-stabilized X-ray unit EXTRAVOLT-225 with programmable control and closed water cooling system

- X-ray television system FILIN -9H1024M together with the system for digital processing and archiving of images, SOVA+

- programmable manipulator of the object with five degrees of movement freedom

- programmable manipulator of X-ray electro-optics with one degree of movement freedom

- automated shutter of the beam

- automated limiting diaphragm of the beam

- automated shutters of X-ray electro-optics

- cabinet with programmable controller of power supply to gearboxes of the motors and with switch panels

- cabin of radiation protection on 160kV with TV system to observe the object position

add to cart add to cart

delete from cart delete from cart

|

|

|

Universal X-ray television complexes of series FILIN-3xx |

Complexes, made to order, completely developed according to the requirements of the client which are designed for the examination of large-size objects. The movement of X-ray TV set, radiator and object with 3-8 degrees of freedom allows the inspection of practically any piece of irregular shape. They are designed for the installation inside the stationary concrete cabin protected against X-rays.

add to cart add to cart

delete from cart delete from cart

|

|

|

SPECIAL COMPLEXES “FILIN-301” |

To inspect welds of high pressure gas check valves of big diameter (radiation thickness of up to 120mm in terms of steel).

The complex consists of:

- high-stabilized X-ray unit EXTRAVOLT-450 with programmable control and closed oil cooling system

- digital radiography system FOSFOMATIC-40 together with the system for processing and archiving of images, SOVA+

- X-ray tube manipulator with 2 degrees of movement freedom

- cart-manipulator of the object with 2 degrees of movement freedom

- cabinet with programmable controller of power supply to gearboxes of the motors and with switch panels

» Details

add to cart add to cart

delete from cart delete from cart

|

|

|

SPECIAL AUTOMATED COMPLEX “FILIN-307” |

For simultaneous inspection of weld end sections in the pipes of big diameter.

The complex consists of:

- high-stabilized X-ray unit EXTRAVOLT-350 with programmable control and closed oil cooling system

- X-ray television system FILIN -9H1024M together with the system for digital processing and archiving of images, SOVA+

- programmable manipulators of X-ray electro-optics with 3 degrees of movement freedom

- programmable manipulator of the pipe with 3 degrees of movement freedom

- descending suspensions for high-voltage generators

- pneumatic units for X-ray electro-optics lifting

- digital laser range finders for the accurate automatic definition of the pipe diameter and coordinates of the pipe ends

- cabinet with programmable controller, controlling the power supply to gear motors and switch panels

- system control desk with sensor panels

» Details

add to cart add to cart

delete from cart delete from cart

|

|

|

Universal X-ray television complexes of series FILIN-4хх |

Complexes, tailor-made, high-capacity, completely developed according to the requirements of the client, for 100% mass control of the objects. Capacity of such systems could achieve thousands objects per shift. In most part of cases similar systems are based on the conveyers or rolling tables, providing quick continuous delivery of the objects to the inspection zone. The movement of X-ray TV-set, radiator and objects with 3-6 degrees of freedom allows the inspection of practically any objects. Some types of the systems are equipped with built-in speed tomography scanner, capable to radiograph the necessary section of the object less than per one minute. The complexes are installed inside own X-ray protected cabins and could be located at practically any production place.

add to cart add to cart

delete from cart delete from cart

|

|

|

SPECIAL AUTOMATIC HIGH-SPEED COMPLEX “FILIN-402” |

To detect and reject inclusions of higher density in light alloy or titanium-bearing alloys.

The complex consists of:

- high-stabilized X-ray unit EXTRAVOLT-160 with programmable control and closed oil cooling system

- 11 high-speed digital X-ray detectors with the system of digital processing and archiving of images SOVA+

- conveyer belt with movement speed of up to 200 mm/sec

- control desk with programmable controller, controlling the system elements

add to cart add to cart

delete from cart delete from cart

|

|

|

UNIVERSAL COMPLEX “FILIN-407-ВТ“ |

For mass control of turbine buckets models, ceramic rods, steel blades of small thickness and light alloy castings in aircraft and car building, with built-in tomography scanner.

The complex consists of:

- high-stabilized X-ray unit EXTRAVOLT-225 with programmable control and closed water cooling system

- flat panel detector of super high resolution FILIN-4747HR with digital system of processing and archiving of the images SOVA+

- programmable conveyer with baskets for the objects

- programmable manipulator of detector with 1 degree of movement freedom

- automated shutters of the chamber

- high-resolution high-speed tomography scanner (option ВТ)

- cabin of radiation protection on 225kV with TV system to observe the object position

- control panel with integrated sensor monitor

Capacity in the radioscopy f the blade models – up to 1500 models per day. Tomography scanning speed of the blade model section makes up 1-2 minutes.

The system could be used for high-quality radioscopy of any objects with maximum radiation thickness of up to 20mm in terms of steel.

» Details

add to cart add to cart

delete from cart delete from cart

|

|

add to cart

add to cart delete from cart

delete from cart

![FILIN X-ARM [C] - универсальные рентгенотелевизионные комплексы с манипулятором типа “C-ARM”](http://testron.ru/images/uploads/b4c17da11c54f37fe63678e4e1aae578.jpg)

![FILIN X-ARM [U] - универсальные рентгенотелевизионные комплексы с манипулятором типа “U-ARM”](http://testron.ru/images/uploads/570c04aac432976ec340e5b7c6413b6d.JPG)