KODAK INDUSTREX M35

category: film processor

|

||

KODAK INDUSTREX M35 IS THE SUPER-COMPACT DESKTOP PROCESSOR, CAPABLE TO PROVIDE ALL ADVANTAGES OF AUTOMATIC PROCESSING OF PHOTOMATERIALS IN SMALL LABORATORIES AND PRODUCTION PREMISES.

The unit allows the saving of money due to the energy saving characteristics and also provides the fulfillment of requirements on the environmental protection and utilization of spent chemical reagents.

Processor INDUSTREX M35 reliable and quality equipment, is an obligatory attribute of modern radiographic laboratory.

USABILITY

• Due to its small area of 67,3 x 75,4 cm, M35 is rather compact, easy transportable and allows saving the space on the floor or on the desk.

• Function of automatic solutions replenishment ensures the convenient and efficient operation. The possibility is provided for the pre-setting of required volumes of replenishing solutions depending on the film type and exposure value.

• At long intervals in the operation the system automatically passes into the standby mode, de-energizing the drive, fan and heater of drying chamber. The full cycle of processing is launched by one pushing of the button. It ideally suits for the application in the systems with alternating mode of loading.

RELIABLE OPERATION

• In order to provide the reliable operation in M35 the same high-quality components like in more powerful processors KODAK INDUSTREX are used.

• The thermostat with microprocessor control, water heat exchanger and developer circulation system provide the constant developing temperature with accuracy of ± 0,3°C.

• Drying with warm air provides the optimum quality of the film surface.

EFFICIENCY

• Saves the costs on energy and heat due to the use of room temperature water in the washing cycle.

• Automatic passage of the system into the standby mode during the long intervals in the operation saves the electric energy and reduces the wear.

• Filter with cell size of 10mcm, installed in the loop of developer circulation, removes solid particles and increases the service life of the solution. The use of tanks for replenishing solutions on 34l with floating covers to slowdown the oxidation also contributes to the service life prolongation.

WIDE CHOICE OF FILMS AND PROCESSING CYCLES

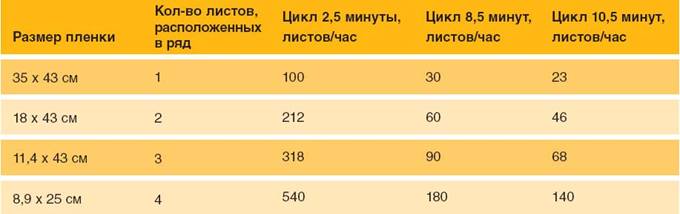

Capacity at the sheet film processing:

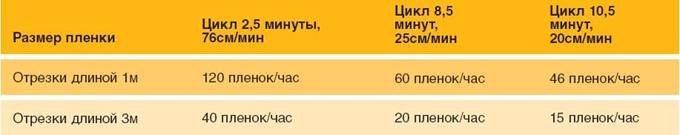

Capacity at the roll film processing: Processor INDUSTREX

M35 can process simultaneously up to 4 films 60 or 70 mm wide or simultaneously 3 films 100mm wide in following quantities:

TECHNICAL CHARACTERISTICS

Types and sizes of films to be processed — sheet films KODAK INDUSTREX, of all standard formats and roll films of up to 36cm wide inclusive and similar by standard sizes to the films of other producers.

Operational principle — continuous roll mechanism with self-feed.

Tanks for processing and chemical reagents — separate tanks for developer, fixing solution and washing by 7.9 l each. It is recommended to use chemical reagents of KODAK INDUSTREX.

Power demand — one-phase, 200-240 V, 50/60 Hz, not more than 20 A.

Overall dimensions

• Width—67,3 cm

• Height—52 cm

• Length—106 cm with feed tray, 75,4 cm without feed tray

• Weight—114 kg with tanks filled

• Weight without solutions—90 kg

• Area occupied—0.5 m2

Drain of spent solutions — one floor drain pipe 75 mm (3 inch) in diameter with throughput of 40l per minute. The drain could be done from every separate tank. The use of pipes made of copper or copper alloys is not allowed.

Ventilation/draft from drying chamber — the processor should be installed in the premise, equipped with ventilation system providing the complete air exchange with rate of 10 or more premise volumes per hour. The separate air duct is required for the draft from the drying chamber. The adapter to connect the pipe of 75mm (3 inch) in diameter is a part of the delivery set.

Safety — processors M35 meet the safety requirements of the rules IFC 380/VDE 806, UL122 and CSA, as well as requirements to radiofrequency noise attenuation VDE 0871 (4/84) limiting class B, DBP 1046/1984, FCC 17 class A. Water supply connections are according to the requirements of the standard DIN 1988 DVGW Sheet W 503.

ADDITIONAL ACCESSORIES

The processor delivery package doesn’t include any accessories for the preparation and storage of replenishing solutions.

Mixers for chemical reagents KODAK 100-K and 100-J, automatic mixer KODAK Automixer II Plus

Mixers for chemical reagents KODAK 100-K and 100-J mix quickly, thoroughly and evenly the processing solutions, providing the order and cleanness. They operate in automatic mode, signalize about critical level of solution and are equipped with guides for the provision with concentrates of developer and fixing solution; which minimizes the risk of operator fault.

Lightproof feed tray for KODAK M35

Additional accessory, saving time and allowing to the operator to work in a normal light or to leave the darkroom just after inserting the exposed film into the tray.

Set of additional tanks for feeding replenishing developer and fixing solutions

KODAK Tank Set, Model M7

Tanks by 34l with possibility to be installed onto the support of the processor (separate delivery)

Support for KODAK M35

This is a reliable support for the processor and equipment, using the sliding shelf, made of stainless steel for the installation of tanks with replenishing solutions on it.

References to the additional information:

Specification on the automatic processor KODAK M-35 in PDF

On the tables:

Размер плёнки – film size

Кол-во листов, расположенных в ряд – quantity of sheets ranged

Цикл минут листов в час – cycle /minutes sheets per hour

Отрезки длиной плёнок в час – segment 1 m long, films per hour

add to cart

add to cart delete from cart

delete from cart